Description

key Benefits

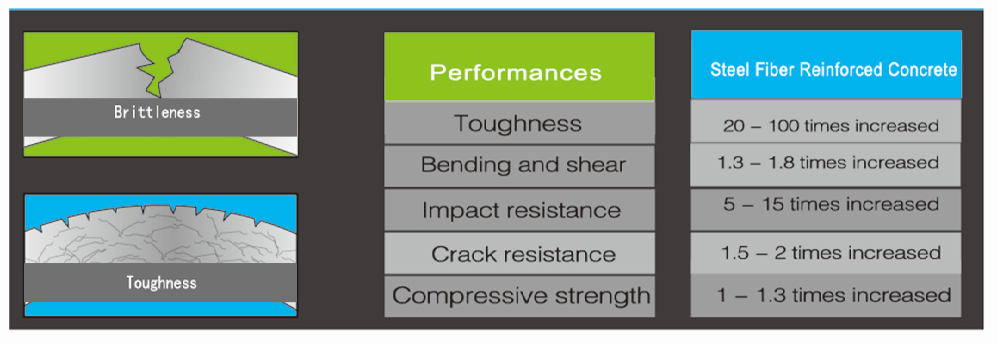

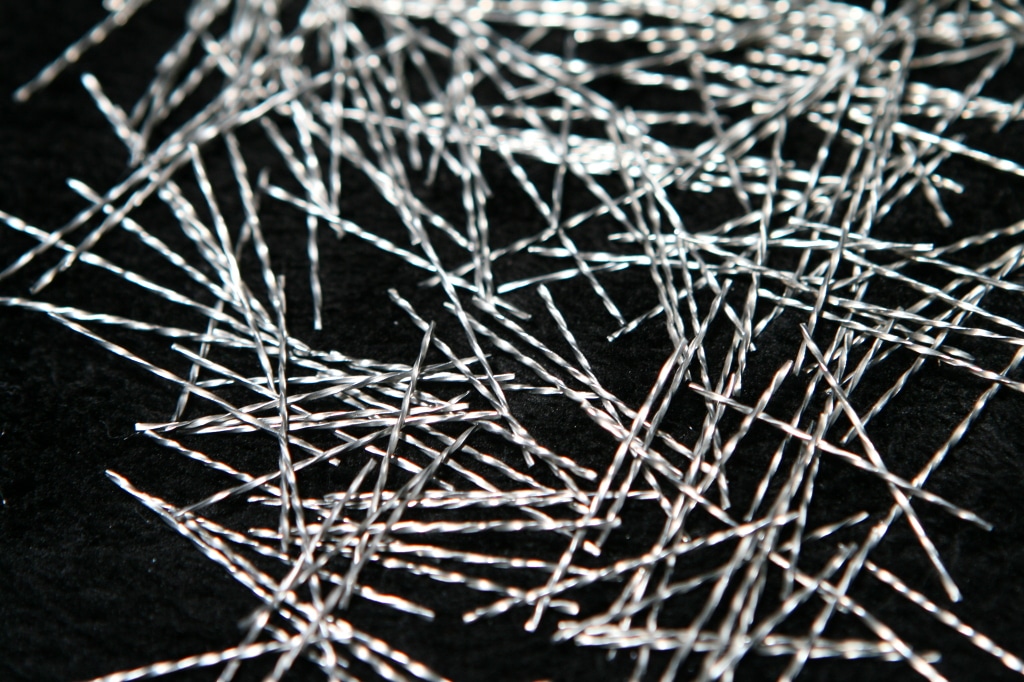

Steel fibers are a popular additive used in concrete to improve its strength, durability, and resistance to cracking. Here are some key benefits of using steel fibers in concrete:

- Increased strength: Steel fibers are added to concrete to increase its flexural and tensile strength, making it more resistant to cracking, spalling, and other forms of damage.

- Improved durability: Concrete reinforced with steel fibers is more durable and resistant to wear and tear, making it ideal for use in high-traffic areas such as industrial floors, parking garages, and bridges.

- Reduced shrinkage and cracking: Steel fibers help reduce shrinkage and cracking in concrete by acting as reinforcement throughout the mixture.

- Cost-effective: Compared to traditional reinforcement methods such as rebar, steel fibers can be a cost-effective alternative, as they are easier to install and require less labor.

- Increased construction speed: Steel fibers can be added directly to the concrete mixture, eliminating the need for additional reinforcement work, which can help speed up the construction process.

steel fibers for concrete price

The cost of steel fiber reinforced concrete (SFRC) can vary depending on several factors such as the type and amount of steel fibers used, the project location, and the size and complexity of the project. Generally speaking, the cost of SFRC is higher than that of regular concrete due to the added cost of steel fibers. The price of steel fibers themselves can range from around $0.10 to $0.50 per pound, but the amount of steel fibers required will depend on the design specifications and the desired level of reinforcement. As an estimate, the cost of steel fibers can add anywhere from $0.50 to $2.00 per cubic yard of concrete.

In addition to the cost of steel fibers, there may be additional expenses involved in the production and placement of SFRC, such as specialized equipment and labor costs. The cost of SFRC can also vary depending on the local market conditions and the availability of materials and labor. It’s important to note that while SFRC may cost more than traditional concrete, it can offer significant benefits in terms of increased strength, durability, and resistance to cracking and other forms of damage, which can ultimately reduce long-term maintenance and repair costs.

Brand strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress and the products and equipment are taking the lead in the world.

-300x300.jpg)

Reviews

There are no reviews yet.