Description

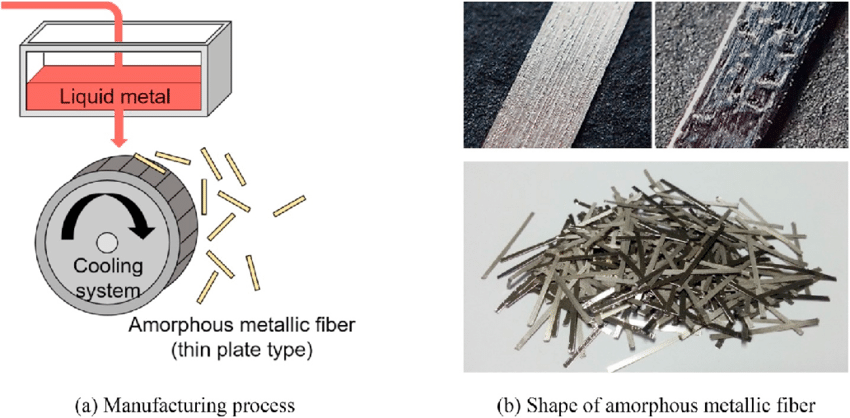

Introduction Of Steel Fiber Manufacturing Process:

Steel fibers are a popular and versatile material used in various construction and industrial applications. They are made by processing steel through a series of steps that transform it from raw materials to finished products. The steel fiber manufacturing process involves several stages, each of which is critical to ensuring the quality and performance of the final product. This article will provide a comprehensive overview of the steel fiber manufacturing process, including the equipment used, the different types of steel fibers produced, and their various applications.

The Steel Fiber Manufacturing Process Overview

The steel fiber manufacturing process begins with the selection of high-quality raw materials, including iron ore, coal, and limestone. These materials are combined and melted in a blast furnace, where they are refined and purified to produce high-quality steel. The molten steel is then cast into billets, which are cut into smaller lengths and sent to the steel fiber manufacturing plant.

Drawing the Steel Fibers

Once the billets have been received at the plant, they are heated and drawn into thin steel fibers using a process known as wire drawing. This process involves pulling the steel through a series of dies, each of which reduces the diameter of the steel fibers. The steel fibers are drawn to precise specifications, ensuring that they meet the required tensile strength, diameter, and other specifications.

Bundling and Processing the Steel Fibers

After the steel fibers have been drawn, they are bundled together and processed to produce steel fibers of various sizes and shapes. This process involves cutting the steel fibers to the required length and shape and then processing them to produce a smooth surface finish. The steel fibers are then packaged and shipped to customers for use in various applications.

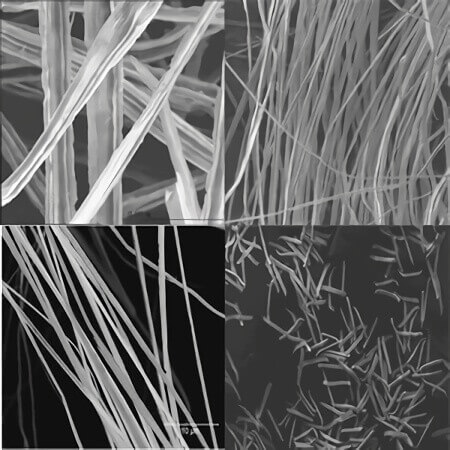

Types of Steel Fibers Produced

There are several different types of steel fibers produced through the steel fiber manufacturing process. These include hooked-end fibers, crimped fibers, straight fibers, and others. Each type of steel fiber has unique properties that make it suitable for a specific application. For example, hooked-end fibers are commonly used in concrete to improve its tensile strength and prevent cracking, while crimped fibers are often used in shotcrete to improve its durability and impact resistance.

Applications of Steel Fibers

Steel fibers are used in a wide range of applications, including construction, infrastructure, mining, and industrial applications. In construction, steel fibers are commonly used in concrete to improve its strength and durability, while in infrastructure applications, they are used in asphalt to improve its durability and resistance to cracking. In mining and industrial applications, steel fibers are used in shotcrete and other materials to improve their strength and resistance to wear and tear.

Conclusion:

The steel fiber manufacturing process is a complex and intricate process that involves several stages, each of which is critical to ensuring the quality and performance of the final product. By understanding the steel fiber manufacturing process, customers can make informed decisions about the types of steel fibers that are best suited to their specific applications. Whether used in construction, infrastructure, mining, or industrial applications, steel fibers offer a range of benefits that make them an ideal choice for a wide range of applications.

-300x300.jpg)

Reviews

There are no reviews yet.