Description

Product Description

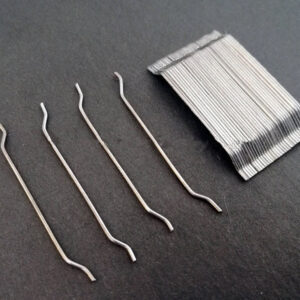

Loose steel fibers are available in different sizes and shapes, depending on the application requirements. They can be made of different types of steel, such as carbon steel, stainless steel, or galvanized steel, depending on the specific performance requirements of the concrete project. The fibers are typically sold in bags, boxes, or bulk quantities, and the packaging may include information about the size, shape, and type of steel fiber. The packaging may also include information about the properties of the steel fibers, such as their tensile strength, ductility, and toughness.

When using loose steel fibers for concrete reinforcement, it is essential to follow the manufacturer’s recommendations regarding the dosage rate and mixing procedure. Improper dosing or mixing of steel fibers can result in reduced performance of the concrete.

Overall, loose steel fibers for sale are a cost-effective reinforcement material for concrete that can significantly enhance its mechanical properties. The selection of the appropriate type and size of steel fiber depends on the specific application requirements and the performance characteristics of the steel fiber.

Prospect

The prospect of loose steel fibers in the construction industry is quite promising. Loose steel fibers are a cost-effective and reliable reinforcement material for concrete that can significantly improve its mechanical properties. The use of steel fibers in concrete has several benefits, including increased strength, durability, and resistance to cracking and shrinkage.

Here are some of the prospects of loose steel fibers in the construction industry:

- Growing Demand: The demand for steel fibers is growing steadily due to increased construction activity worldwide. Steel fibers are used in various applications, including industrial flooring, precast concrete products, shotcrete, and tunnel lining.

- Cost-Effective: Loose steel fibers are a cost-effective reinforcement material for concrete, as they are relatively inexpensive compared to other reinforcement materials such as rebar or mesh.

- Improved Performance: The addition of steel fibers to concrete can significantly improve its mechanical properties, including its tensile strength, toughness, and durability. Steel fibers can also reduce the occurrence of cracking and improve the bond between the concrete matrix and reinforcing bars.

- Innovation and Advancements: The steel fiber industry is continuously evolving, and innovations and advancements are being made in the production and application of steel fibers. For example, specialized coatings can be applied to steel fibers to improve their performance in specific applications.

- Sustainable Construction: The use of steel fibers in concrete can contribute to sustainable construction practices by reducing the amount of energy and materials required for construction. Steel fibers can also extend the lifespan of concrete structures, reducing the need for maintenance and replacement.

.png)

Advantages of loose steel fibers

Loose steel fibers are reinforcement material used in concrete that offers several advantages over other reinforcement materials such as rebar or mesh. Some of the common advantages of loose steel fibers are:

- Increased Strength: The addition of steel fibers to concrete can significantly increase its tensile strength, making it more resistant to cracking and damage.

- Improved Durability: Steel fibers can improve the durability of concrete by reducing the rate of deterioration caused by environmental factors such as freeze-thaw cycles, chemical exposure, and abrasion.

- Reduced Cracking: Steel fibers can reduce the occurrence of cracking in concrete, resulting in a more durable and long-lasting concrete structure.

- Enhanced Bonding: Steel fibers can improve the bonding between the concrete matrix and reinforcing bars, resulting in a stronger and more durable concrete structure.

- Cost-Effective: Loose steel fibers are a cost-effective reinforcement material for concrete, as they are relatively inexpensive compared to other reinforcement materials such as rebar or mesh.

- Easy to Handle and Install: Loose steel fibers are easy to handle and install in concrete, making them a popular choice for construction projects of various sizes and complexities.

- Improved Construction Speed: The use of steel fibers can improve the construction speed of concrete structures by reducing the need for additional reinforcing materials and simplifying the construction process.

Manufacturer introduction

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress and the products and equipment are taking the lead in the world.

.jpg)

Reviews

There are no reviews yet.