Description

Introduction

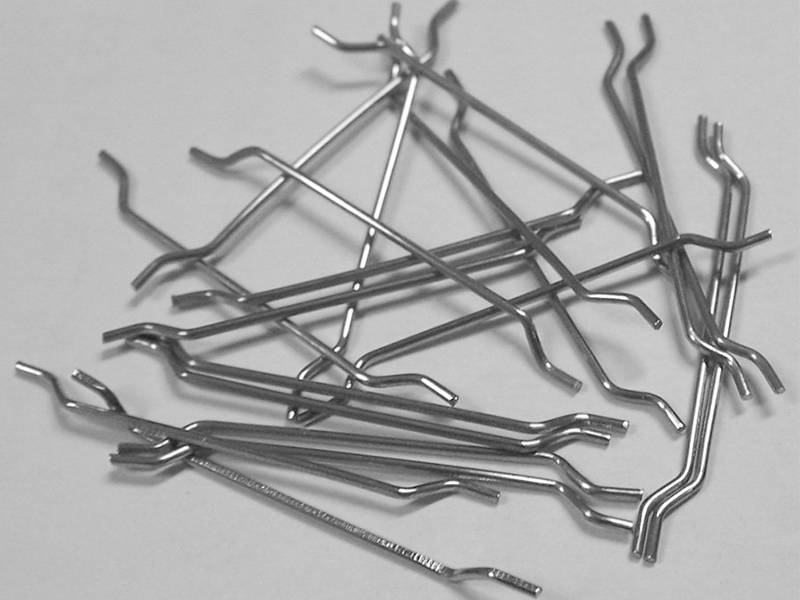

Hooked end steel fiber is a type of reinforcing material that is added to concrete to improve its mechanical properties. The fibers have a unique hooked shape at the end, which enhances their bond with the concrete and provides greater support. This article will introduce you to hooked end steel fiber for concrete, including its composition, manufacturing process, and benefits. We will also discuss its applications and advantages over traditional reinforcement methods.

Hooked end steel fiber is a type of reinforcing material that is made from high-strength steel wire. The fibers have a unique hooked shape at the end, which provides a better bond with the concrete and enhances their ability to withstand greater stress. Hooked end steel fibers are typically added to concrete mixtures in small quantities to improve their mechanical properties.

Advantages

Improved Strength and Durability

One of the main advantages of using hooked end steel fiber for concrete reinforcement is its ability to improve the strength and durability of the material. The fibers provide additional support to the concrete, allowing it to withstand greater stress and resist cracking. This can be particularly useful in high-traffic areas like highways, bridges, and parking lots.

Better Crack Resistance

Another advantage of using hooked end steel fiber is its ability to improve the crack resistance of concrete. By reinforcing the concrete with threads, the material is better able to withstand the tensile stresses that can cause cracking. This can help to increase the lifespan of concrete structures and reduce the need for costly repairs.

Ease of Use

Hooked end steel fiber is also easy to use, making it a popular choice among construction professionals. Unlike traditional reinforcement methods like rebar or mesh, fibers can be easily added to the concrete mixture without the need for additional preparation or installation. This can save time and reduce labor costs on construction projects.

Cost-Effectiveness

Using hooked end steel fiber for concrete reinforcement can also be cost-effective in the long run. While the initial cost of the fibers may be higher than traditional reinforcement methods, the improved strength and durability of the concrete can lead to reduced maintenance and repair costs over time. This can result in significant cost savings for construction projects in the long term.

Environmental Friendliness

Finally, using hooked end steel fiber for concrete reinforcement is also environmentally friendly. The fibers are made from recyclable materials and can be reused in other construction projects. Additionally, the improved crack resistance of the reinforced concrete can help to reduce the need for repairs and replacements, which can help to reduce waste and conserve resources.

Overall, the numerous advantages of using hooked end steel fiber for concrete reinforcement make it a popular choice among construction professionals. Its ability to improve strength and durability, crack resistance, ease of use, cost-effectiveness, and environmental friendliness make it a versatile and effective reinforcement material for a variety of concrete applications.

Applications of hooked end steel fiber

- Industrial flooring: Hooked end steel fibers can be added to concrete to create durable and wear-resistant industrial flooring. The steel fibers improve the strength and toughness of the concrete, making it more resistant to abrasion from heavy machinery and foot traffic.

- Pavements: Hooked end steel fibers are also used in constructing pavements, such as highways and airport runways. The fibers help to increase the strength and durability of the concrete, reducing the likelihood of cracking and extending the lifespan of the pavement.

- Precast concrete products: Hooked end steel fibers can be added to precast concrete products, such as retaining walls and bridge components, to increase their strength and durability. This makes the products more resistant to the stresses and strains of transportation and installation.

- Shotcrete: Hooked end steel fibers can be used in shotcrete, which is a type of concrete that is sprayed onto surfaces using a high-pressure hose. The fibers help to improve the cohesion and tensile strength of the shotcrete, making it more resistant to cracking and spalling.

- Tunnel linings: Hooked end steel fibers are often used in the construction of tunnel linings, where the concrete is subject to high pressures and stresses. The fibers help to increase the strength and ductility of the concrete, reducing the likelihood of cracking and improving its ability to withstand the forces generated by the surrounding rock.

Brand Strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained

ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed significant progress, and the products and equipment are taking the lead in the world.

.jpg)

.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.