Description

Details of 316 Stainless Steel Fiber Production

316 stainless steel fiber is a type of metallic fiber made from 316-grade stainless steel. It is a highly corrosion-resistant material that is commonly used in high-performance applications where strength, durability, and resistance to harsh environments are required. This type of stainless steel fiber has excellent tensile strength, flexural strength, and impact resistance, making it suitable for reinforcing concrete structures such as industrial floors, precast concrete products, and shotcrete applications. It is also used in the production of high-stress composites, such as fiber-reinforced polymers, and in the aerospace and automotive industries.

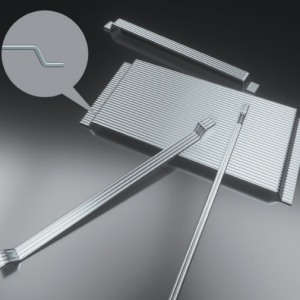

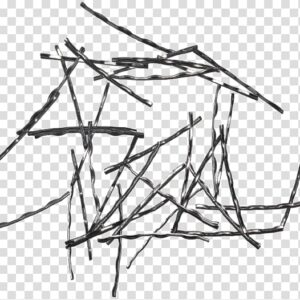

This type of stainless steel fiber is available in various forms, including straight fibers, crimped fibers, and hooked-end fibers. The fibers can be added to the concrete mix during the mixing process or applied as a surface treatment to existing concrete structures. In addition to its mechanical properties, 316 stainless steel fiber also offers excellent resistance to corrosion and oxidation, making it suitable for use in harsh and corrosive environments. It is also resistant to high temperatures and can maintain its strength and durability at elevated temperatures.

Application

316 stainless steel fiber has a wide range of applications in various industries due to its excellent mechanical properties and corrosion resistance. Some common applications of 316 stainless steel fiber include:

- Reinforcing Concrete: 316 stainless steel fiber is commonly used to reinforce concrete structures such as industrial floors, precast concrete products, and shotcrete applications. The fibers improve the tensile strength, flexural strength, and impact resistance of concrete, making it more durable and resistant to damage.

- Composites: 316 stainless steel fiber is used in the production of high-stress composites, such as fiber-reinforced polymers. The fibers enhance the strength and durability of the composite, making it suitable for use in aerospace, automotive, and other high-performance applications.

- Corrosive Environments: 316 stainless steel fiber is highly resistant to corrosion and oxidation, making it suitable for use in harsh and corrosive environments. It is commonly used in marine, offshore, and chemical processing industries.

- High-Temperature Applications: 316 stainless steel fiber can maintain its strength and durability at elevated temperatures, making it suitable for use in high-temperature applications such as furnaces and heat exchangers.

- Textiles: 316 stainless steel fiber can be used in the production of textiles, such as clothing and filtration materials, to enhance their strength and durability.

Properties Of 316 Stainless Steel Fiber

- High Tensile Strength: 316 stainless steel fiber has excellent tensile strength, making it suitable for use in high-stress applications. It has a tensile strength of approximately 200,000 psi, which is higher than that of many other metallic fibers.

- Corrosion Resistance: 316 stainless steel fiber is highly resistant to corrosion and oxidation, making it suitable for use in harsh and corrosive environments. It contains a high percentage of chromium, which forms a protective oxide layer on the surface of the fiber, preventing corrosion.

- High-Temperature Resistance: 316 stainless steel fiber can maintain its strength and durability at high temperatures, making it suitable for use in high-temperature applications such as furnaces and heat exchangers.

- Flexibility: 316 stainless steel fiber is highly flexible and can be easily shaped and molded to suit different applications. It can be formed into different shapes and sizes, including straight fibers, crimped fibers, and hooked-end fibers.

- Ductility: 316 stainless steel fiber is highly ductile, meaning it can be deformed without breaking. This property makes it suitable for use in applications where the material is subjected to bending or twisting.

- Magnetic: 316 stainless steel fiber is magnetic, which can be an advantage in certain applications where magnetic properties are required.

Our Brand Strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained

ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments.

Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress, and the products and equipment are taking lead in the world.

.jpg)

Reviews

There are no reviews yet.