In this article, we will explore the factors influencing the cost of steel fiber reinforced concrete and how it can be effectively utilized. From material selection to project planning.

Understanding the Cost of Steel Fiber Reinforced Concrete

The cost of steel fiber reinforced concrete is influenced by various factors that need to be carefully considered during project planning and budgeting.

These factors include the type and quality of fibers used, the required fiber dosage, the complexity of the project, and the local market conditions.

Factors Affecting the Cost of Steel Fiber Reinforced Concrete

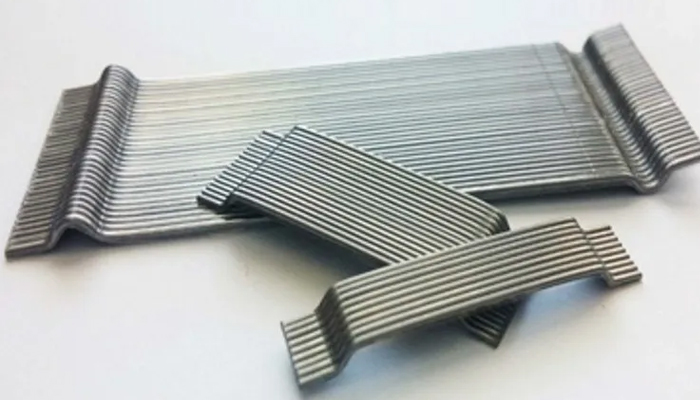

Fiber Type and Quality:

Different types of steel fibers are available in the market, varying in quality and performance characteristics. Higher-quality fibers may come at a higher cost but provide superior reinforcement properties. Choosing the appropriate fiber type based on project requirements can help optimize costs without compromising performance.

Fiber Dosage:

The required fiber dosage depends on the desired concrete strength, crack resistance, and project specifications. Higher fiber dosages typically result in increased material costs.

However, the optimal dosage should be determined by considering the specific project requirements and consulting with experts in the field.

Project Complexity:

The complexity of the construction project, such as the design intricacy, structural requirements, and site conditions, can influence the cost of steel fiber reinforced concrete. Projects with unique challenges may require additional engineering expertise, which can impact overall costs.

Local Market Conditions:

The cost of materials, including steel fibers, can vary depending on the local market conditions, such as supply and demand, transportation costs, and regional pricing. Conducting thorough market research and sourcing materials from reliable suppliers can help optimize costs.

Case Study: Cost Optimization of Steel Fiber Reinforced Concrete in a High-Rise Building

A notable example of cost optimization using steel fiber reinforced concrete can be observed in the construction of a high-rise building. By carefully selecting the appropriate fiber type and dosage, the project team achieved the desired strength and crack resistance while minimizing material costs.

Additionally, the improved construction speed and reduced maintenance requirements of the steel fiber reinforced concrete contributed to long-term cost savings for the building owner.

Conclusion:

In conclusion, optimizing the cost of steel fiber reinforced concrete involves considering various factors, such as fiber type and quality, dosage, project complexity, and local market conditions. By carefully evaluating these factors, construction professionals can achieve both cost-efficiency and high-performance results.

Incorporating steel fiber reinforced concrete in construction projects offers enhanced strength, durability, and crack resistance, making it a valuable choice for a wide range of applications. Stay ahead in the construction industry by harnessing the benefits of cost-effective steel fiber reinforced concrete.