Concrete is one of the most widely used building materials due to its durability and strength. However, it can still be subject to cracking and fragmentation under certain conditions. Loose hooked end steel fiber in concrete is a cost-effective and efficient solution to improve its strength and durability. In this article, we will explore how the use of loose hooked end steel fiber can enhance concrete strength, its benefits, and how it can be applied in construction projects.

What is Loose Hooked End Steel Fiber in Concrete?

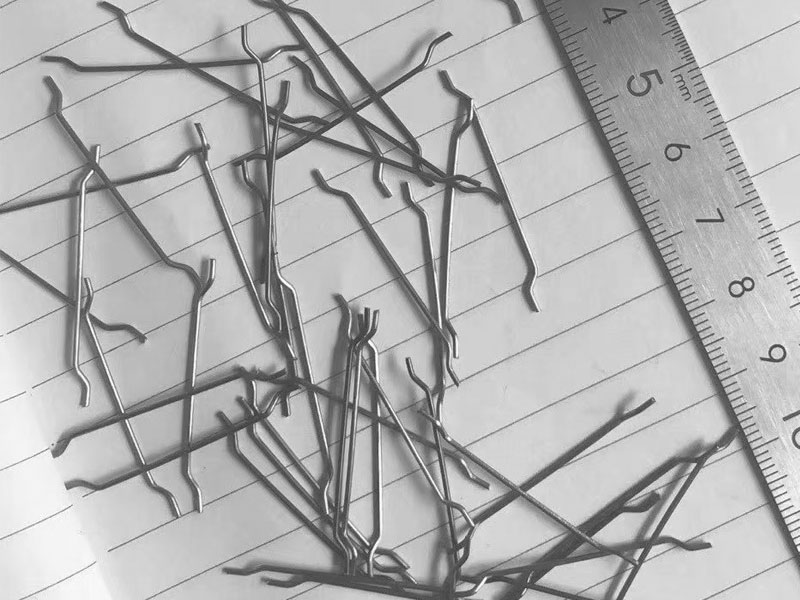

Loose hooked end steel fiber is a type of reinforcement material that is added to concrete mixtures to improve its strength and durability. These fibers are typically made of high-strength steel and are designed with hooked ends that interlock with other fibers and the concrete mix. The use of these fibers helps to prevent cracking and fragmentation, which can lead to costly repairs and maintenance.

Benefits of Using Loose Hooked End Steel Fiber in Concrete

The use of loose hooked end steel fiber in concrete offers several benefits. Firstly, it improves the tensile strength of the concrete, making it more resistant to cracking and fragmentation. Secondly, the fibers also help to improve the concrete’s durability, making it more resistant to the effects of weathering and other environmental factors. Finally, the addition of steel fibers to concrete can also improve its resistance to impact and abrasion, making it ideal for use in high-traffic areas.

How to Apply Loose Hooked End Steel Fiber in Concrete

The process of adding loose hooked end steel fiber to concrete is relatively simple. The fibers are typically added during the mixing process and are evenly distributed throughout the mixture. The amount of fiber added will depend on the specific requirements of the project but typically ranges from 20 to 50 kg/m3. It is important to ensure that the fibers are evenly distributed throughout the concrete to ensure maximum effectiveness.

Examples of Loose Hooked End Steel Fiber Applications

Loose hooked end steel fiber in concrete can be used in a variety of construction projects, including industrial flooring, precast concrete, and shotcrete applications. For example, in industrial flooring, the use of steel fiber can help to improve the wear resistance and durability of the flooring. In precast concrete, the use of steel fiber can help to improve the strength and durability of the precast elements. In shotcrete applications, the use of steel fiber can help to improve the impact resistance and durability of the sprayed concrete.

In conclusion, the use of loose hooked end steel fiber in concrete is a cost-effective and efficient way to improve the strength and durability of concrete. Its benefits include improved tensile strength, durability, and resistance to impact and abrasion. The application of steel fiber in concrete is relatively simple and can be used in a variety of construction projects. By incorporating loose hooked end steel fiber in concrete, construction projects can benefit from longer-lasting and more durable concrete structures.

In summary, loose hooked end steel fiber in concrete is an excellent solution for improving the strength and durability of concrete structures. Its benefits are numerous, including improved tensile strength, durability, and resistance to impact and abrasion. The process of incorporating steel fiber in concrete is relatively simple and can be used in various construction projects. With the use of loose hooked end steel fiber, construction projects can benefit from longer-lasting and more durable concrete structures, leading to lower maintenance costs and increased safety.