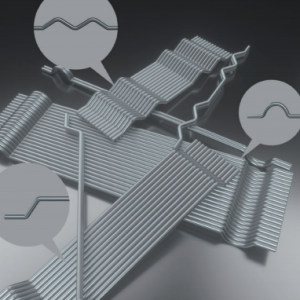

Description

Benefits Of Aerotech Steel Fiber

- Improved durability: Aerotech steel fiber can help to reduce the risk of cracking and improve the durability of concrete structures. This can result in longer service life and reduced maintenance costs.

- Enhanced mechanical properties: Aerotech steel fiber provides improved mechanical properties to the concrete, such as increased toughness, ductility, and resistance to cracking and impact. This can help to improve the overall performance of the structure.

- Cost-effective: Aerotech steel fiber provides a cost-effective solution to traditional reinforcement methods, such as rebar and mesh. It reduces construction time and labor costs, making it a cost-effective solution for many construction projects.

- Increased load-bearing capacity: Aerotech steel fiber can help to increase the load-bearing capacity of concrete structures, making them better suited for heavy traffic and high loads.

- Corrosion resistance: Aerotech steel fiber is typically made of stainless steel or coated with a protective layer, which enhances its corrosion resistance. This makes it well-suited for use in harsh environments, such as marine or industrial settings.

- Improved construction efficiency: Aerotech steel fiber can help to improve construction efficiency by reducing the need for additional reinforcement materials and simplifying the reinforcement process.

Using Of Aerotech Steel Fiber

To use Aerotech steel fiber effectively, it is important to follow proper mixing and placement procedures. Here are some key steps to using Aerotech steel fiber:

- Select the appropriate type and dosage of Aerotech steel fiber based on the specific project requirements and conditions.

- Add the Aerotech steel fiber to the concrete mix during the mixing process. Ensure that the steel fibers are evenly distributed throughout the mixture to provide uniform reinforcement.

- Use proper equipment and techniques during concrete placement to avoid segregation and ensure proper consolidation of the concrete. This includes using vibrators or other consolidation methods to ensure that the concrete fills all voids and spaces in the formwork.

- Cure the concrete properly to ensure that it achieves the desired strength and durability. This may involve using curing compounds, wet curing, or other methods to maintain the proper moisture and temperature levels during the curing process.

- Inspect the Aerotech steel fiber reinforced concrete for any defects or damage after placement and curing. This will help to identify any issues that may need to be addressed before the structure is put into service.

Application scene display

application of Aerotech steel fiber

Industrial Strength

We mainly produce Hooked End Steel Fibers and Micro Steel Fibers, with an annual production capacity of 55,000 tons. It is the largest steel fiber manufacturer in China. The factory has obtained

ISO9001/14001/45001 certification and the products have also obtained the EU CE level 1 certification and South Korea KS certification. Establish a joint laboratory with the Hebei University of Technology to conduct concrete-related experiments. Over the years, Hengfeng has been making great efforts to improve the overall business and build a good image. First, measures have been made to achieve zero pollutant emissions. Second, an R&D center has been established to develop and research new products together with well-known colleges and specialists. As a result, our technology has witnessed big progress, and the products and equipment are taking lead in the world.

Factory Environment

Reviews

There are no reviews yet.