Builders and contractors often face a dilemma – should they go for steel fibers or synthetic fibers? We will explore the key differences between steel fibers vs. synthetic fibers.

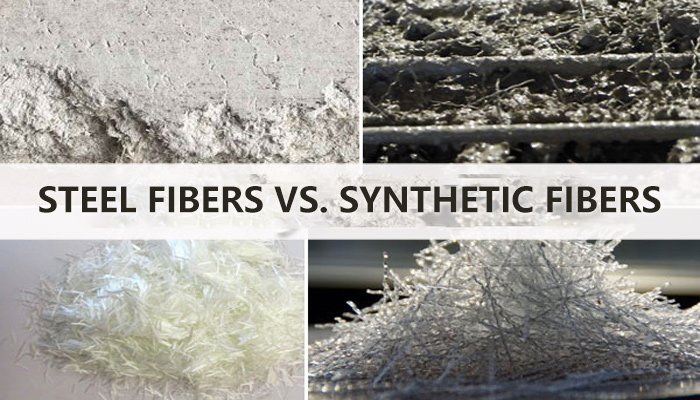

Steel Fibers vs. Synthetic Fibers

What are Steel Fibers?

Steel fibers are made from steel wire that has been drawn and cut into short lengths. They are commonly used in concrete to improve its tensile strength and durability. Steel fibers come in different sizes and shapes, and can be used in various applications such as flooring, roofing, and precast concrete products.

What are Synthetic Fibers?

Synthetic fibers, on the other hand, are made from synthetic materials such as polypropylene, polyester, or nylon. They are also used to improve the tensile strength and durability of concrete but have some distinct advantages over steel fibers. Synthetic fibers are lighter, less expensive, and easier to install than steel fibers.

Which is Better – Steel Fibers or Synthetic Fibers?

The choice between steel fibers and synthetic fibers depends on several factors such as the type of project, the required strength and durability, and the budget. Steel fibers are better suited for high-stress applications such as industrial flooring and heavy-duty infrastructure projects, while synthetic fibers are ideal for residential and commercial projects where cost-effectiveness is a major concern.

How Do Steel Fibers and Synthetic Fibers Compare in Terms of Durability?

Steel fibers are generally more durable than synthetic fibers, thanks to their higher tensile strength and resistance to corrosion. However, synthetic fibers are also known for their excellent durability and can last for decades with proper maintenance.

What are the Installation Methods for Steel Fibers and Synthetic Fibers?

Steel fibers can be installed using various methods such as dry-mix, wet-mix, and pre-stressed concrete. Synthetic fibers, on the other hand, can be installed using dry-mix or wet-mix methods.

What are the Cost Differences Between Steel Fibers and Synthetic Fibers?

Synthetic fibers are generally less expensive than steel fibers, mainly due to their lower production cost and lighter weight. However, the cost difference can vary depending on the specific type of fiber and the project requirements.

Can Steel Fibers and Synthetic Fibers Be Used Together?

Yes, steel fibers and synthetic fibers can be used together in a single project to achieve better results. This is known as hybrid fiber reinforcement, and it can offer improved strength, durability, and cost-effectiveness compared to using a single type of fiber.

Conclusion:

In conclusion, both steel fibers and synthetic fibers have their own set of advantages and disadvantages, and the choice between them depends on the specific requirements of the project. By considering factors such as durability, cost-effectiveness, and installation methods.

Builders and contractors can make an informed decision about which type of fiber to use. Whether you choose steel fibers or synthetic fibers, the most important thing is to ensure that your project meets the required standards and specifications for durability and safety.