Dive into the world of construction innovation with a comprehensive exploration of steel fiber mesh concrete. This article presents a balanced analysis of its pros and cons, offering valuable insights for engineers and builders seeking to harness the potential of this remarkable material in their projects.

Introduction: Pioneering Construction Strength with Steel Fiber Mesh Concrete

In the realm of modern construction, steel fiber mesh concrete has emerged as a game-changer, offering enhanced structural integrity and durability. This article delves into the pros and cons of this innovative material, shedding light on its benefits and potential drawbacks.

Understanding Steel Fiber Mesh Concrete

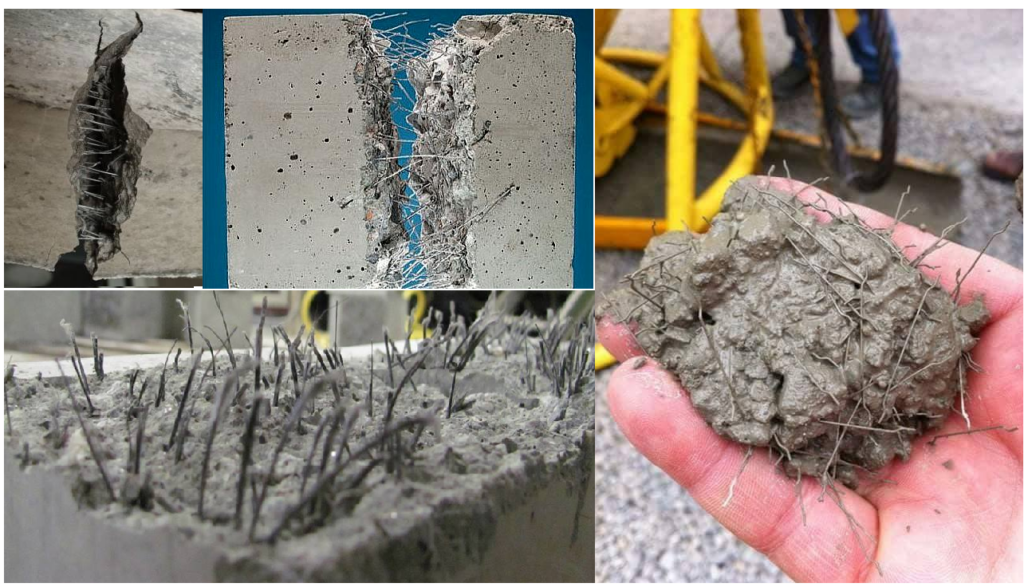

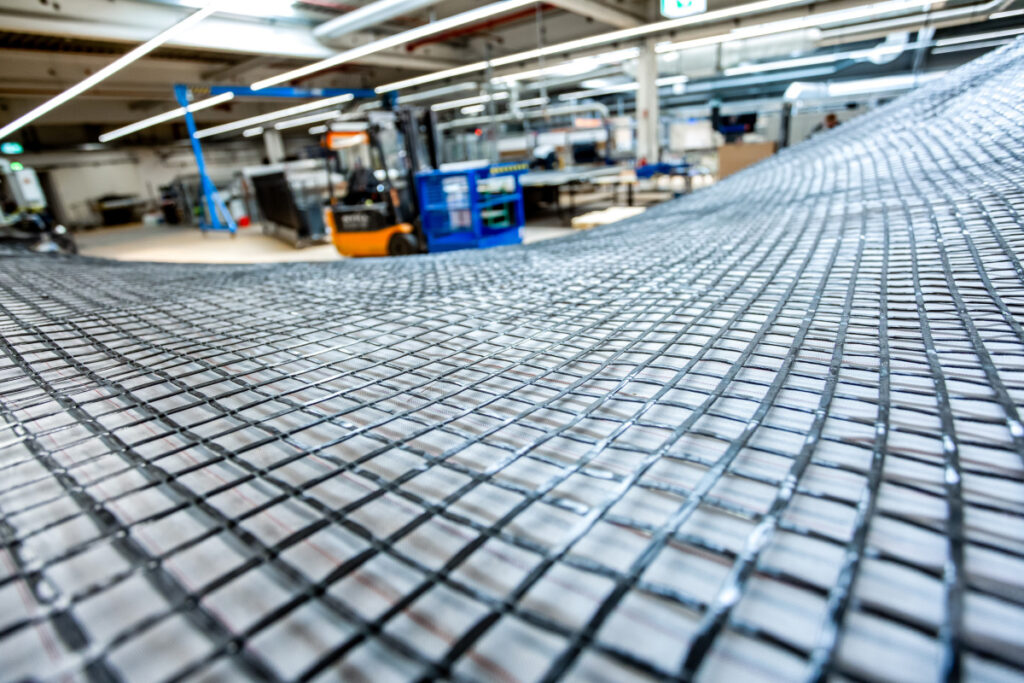

Steel fiber mesh concrete integrates tiny, evenly distributed steel fibers within the concrete matrix. These fibers act as reinforcement, providing improved tensile strength and crack resistance. The result is a composite material that combines the benefits of traditional concrete with the added strength of steel.

Pros of Steel Fiber Mesh Concrete

- Enhanced Strength: The incorporation of steel fibers significantly boosts the concrete’s tensile strength, reducing the risk of cracks and improving overall durability.

- Crack Control: The presence of steel fibers disperses energy upon cracking, minimizing crack widths and preventing their propagation.

- Reduced Maintenance: Structures built with steel fiber mesh concrete require less maintenance due to its enhanced durability, saving both time and resources.

Cons of Steel Fiber Mesh Concrete

- Uniform Dispersion Challenge: Ensuring consistent distribution of steel fibers throughout the concrete mixture can be challenging, potentially leading to uneven reinforcement.

- Mix Design Complexity: Designing the concrete mix with the right proportions of fibers while maintaining workability can be intricate.

- Cost Factor: Steel fiber mesh concrete can be more expensive than traditional concrete due to the additional cost of steel fibers.

Applications and Suitability

Steel fiber mesh concrete finds its applications in various scenarios. For instance, it is well-suited for industrial floors, warehouse pavements, and tunnel linings due to its crack-resistant properties. However, it might not be the ideal choice for projects with stringent aesthetic requirements, as the fibers might slightly affect the surface appearance.

Case Studies

The construction of a warehouse floor using steel fiber mesh concrete showcased its remarkable durability against heavy machinery loads, reducing maintenance needs. However, a project involving decorative concrete elements opted for traditional reinforcement due to the desired surface finish.

Future Prospects

As technology evolves, the challenges associated with uniform fiber dispersion and mix design are being addressed. Researchers are working on optimizing steel fiber mesh concrete to make it more cost-effective and versatile for a broader range of applications.

Conclusion: Striking a Balance for Optimal Construction

Steel fiber mesh concrete represents a fusion of innovation and tradition, offering both enhanced strength and crack resistance. While it carries certain challenges like uniform fiber dispersion and cost considerations, its advantages make it a worthy contender in modern construction. By weighing its pros and cons against project requirements, builders can make informed decisions, contributing to a stronger and more resilient built environment.