Steel Fiber Features: Uncovering the Key Characteristics that Make Steel Fiber Reinforced Concrete a Superior Building Material. Steel fiber reinforced concrete (SFRC) is rapidly becoming one of the most popular building materials in the construction industry.

The Benefits of Steel Fiber Reinforced Concrete

One of the most important about steel fiber features is it can reinforce concrete which is a composite material that is made by adding steel fibers to traditional concrete. The addition of steel fibers greatly enhances the mechanical properties of the concrete, making it stronger, more durable, and more resistant to cracking and deformation. The key benefits of SFRC include:

- Increased strength: Steel fibers enhance the tensile strength of the concrete, making it more resistant to cracking and deformation under load.

- Improved durability: Steel fibers improve the durability of the concrete, making it more resistant to damage caused by weathering, freeze-thaw cycles, and chemical attacks.

- Enhanced ductility: Steel fibers improve the ductility of the concrete, allowing it to bend and deform without fracturing.

- Better impact resistance: Steel fibers enhance the impact resistance of the concrete, making it more resistant to damage caused by impact or shock loading.

- Improved fire resistance: Steel fibers enhance the fire resistance of the concrete, making it more resistant to high temperatures and reducing the risk of structural collapse in the event of a fire.

Types of Steel Fibers Used in SFRC

There are several types of steel fibers that can be used in SFRC, each with its own unique steel fiber features and benefits. Some of the most common types of steel fibers include:

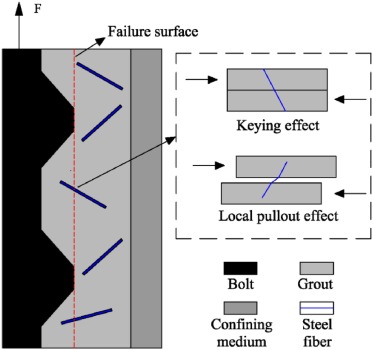

- Hooked-end steel fibers: These fibers have a hooked shape on one end, which helps to anchor them in the concrete and improve their bonding strength.

- Straight steel fibers: These fibers are straight and smooth, and are commonly used in low-dosage applications where a high degree of workability is required.

- Deformed steel fibers: These fibers have a deformed shape, which increases their bonding strength and improves their ability to resist pull-out forces.

- Stainless steel fibers: These fibers are made from stainless steel and offer superior corrosion resistance and durability in harsh environments.

Factors to Consider When Choosing Steel Fibers for SFRC

When choosing steel fibers for SFRC, there are several factors to consider, including:

- Fiber length: Longer fibers offer greater reinforcement, but can be more difficult to mix and distribute evenly throughout the concrete.

- Fiber diameter: Thicker fibers offer greater reinforcement, but can also be more difficult to mix and distribute evenly.

- Fiber shape: Hooked-end fibers offer greater bonding strength, while deformed fibers offer greater resistance to pull-out forces.

- Dosage rate: The number of steel fibers added to the concrete can vary depending on the specific application and desired performance characteristics.

- Corrosion resistance: In harsh environments, such as coastal or industrial areas, stainless steel fibers may be preferred to improve the durability and longevity of the SFRC.

- Compatibility: The steel fibers used in SFRC must be compatible with the other components of the concrete mix, including cement, aggregates, and admixtures.

In summary, steel fiber reinforced concrete is a high-performance material that offers numerous benefits over traditional concrete. The key steel fiber features that make SFRC superior include increased strength, improved durability, enhanced ductility, better impact resistance, and improved fire resistance.

When choosing steel fibers for SFRC, it is important to consider factors such as fiber length, diameter, shape, dosage rate, corrosion resistance, and compatibility with other components of the concrete mix. By selecting the right steel fibers for your SFRC project, you can ensure that your structure is strong, durable, and built to last.